Food Safety

Riverview is committed to using the most effective food safety systems available and working with our regulatory partners at the Canadian Food Inspection Agency (CFIA) to produce the highest quality poultry products.

HACCP Recognition

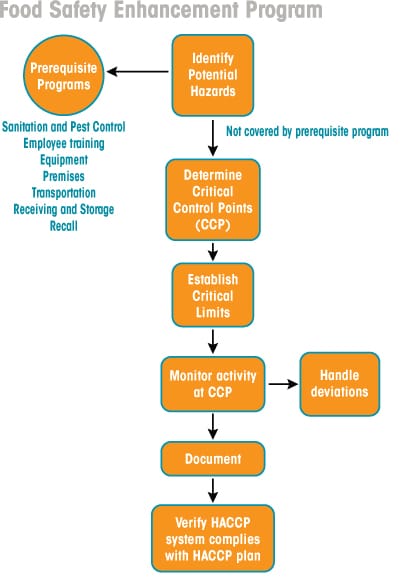

The cornerstone of Riverview’s commitment to food safety is a HACCP-based (Hazard Analysis Critical Control Points) food safety system. HACCP was developed in the 1960s when NASA asked Pillsbury to design and manufacture food for space travel. Since then, it has been used around the world as a tool for combining traditional inspection methods with a scientific approach to food safety.

The HACCP system is based on the following seven principles:

- Identify hazards–biological, chemical and physical–at all stages of production;

- Eliminate hazards or minimize the likelihood of their occurrence;

- Establish what the critical limit is (the point where the acceptable becomes the unacceptable) and formulate suitable preventative measures;

- Establish procedures to monitor the critical control points where control over a food safety hazard can be applied;

- Establish corrective actions to be taken when the critical control point is not under control;

- Establish procedures to verify that the system is working properly;

- Establish effective record keeping to document the HACCP system.

- HACCP works by providing control throughout the manufacturing process at critical control points where hazards can be prevented, eliminated or managed to acceptable levels.

Control measures are in place throughout the manufacturing process with Canadian Food Inspection Agency representation on-site to verify safe food handling practices. Riverview Poultry works in partnership with the Canadian Food Inspection Agency to assure that the appropriate steps have been taken to monitor, maintain and reevaluate food safety systems (prerequisite programs and HACCP) on a regular basis.

Example of Hazard and Critical Control Point

Certainly, the biological hazard most commonly associated with food is Bacterial growth. Given a too cozy (i.e. warm) environment, bacteria will grow at an exponential rate which is why it’s never a good idea to thaw chicken anywhere other than in the refrigerator.

Hazard:

bacterial growth if chicken is not chilled to less than 4 degrees Celsius within a defined time limit.

Critical Control Point:

Chiller tank where chicken goes to cool off

Critical Limit:

4 degrees Celsius

Monitor:

Take the temperature of ten chickens every two hours as they exit the final chiller

Documentation:

Chilling Report

Verification:

Quality assurance monitors documentation for completeness, observes monitoring on-site

The chiller is only one of many critical control points at Riverview Poultry where biological hazards are managed.